|

Fungi form a wide network of thin threads called “mycelium”, which can be used to create many things. You’ve probably already seen biodegradable packaging or tasted meat substitutes. More generally, the production industry relies heavily on microbial enzymes. From textile to detergents and recycling paper, from making cheese to brewing beer, it is done with the help of microbial enzymes. |

||

| Bacteria | Fungi | Plasmids | |

Bacteria

Paraburkholderia sacchari (LMG 19450T)

Paraburkholderia sacchari is known for its ability to produce polyhydroxyalkanoates (PHAs), an eco-friendly alternative to conventional plastics due to their biodegradability and potential for various applications. As PHA polymers are synthesized, they are accumulated within the bacterial cells in the form of PHA granules, serving as storage compartments for PHAs and allowing the bacterium to store excess carbon and energy.

Paraburkholderia sacchari can utilize directly a variety of carbon sources, including sugars, organic acids and fatty acids that are first converted into acetyl-CoA, which serves as the precursor for PHA synthesis.

The ability of Paraburkholderia sacchari to synthesize PHAs offers potential applications in bioplastics, packaging materials, medical devices, and other industries where biodegradable and sustainable materials are desirable.

Start a Research on Biopolymer Polyhydroxyalkanoate (PHA): A Review. Tan et al., Polymers (2014)

Lysinibacillus sphaericus (LMG 7134T)

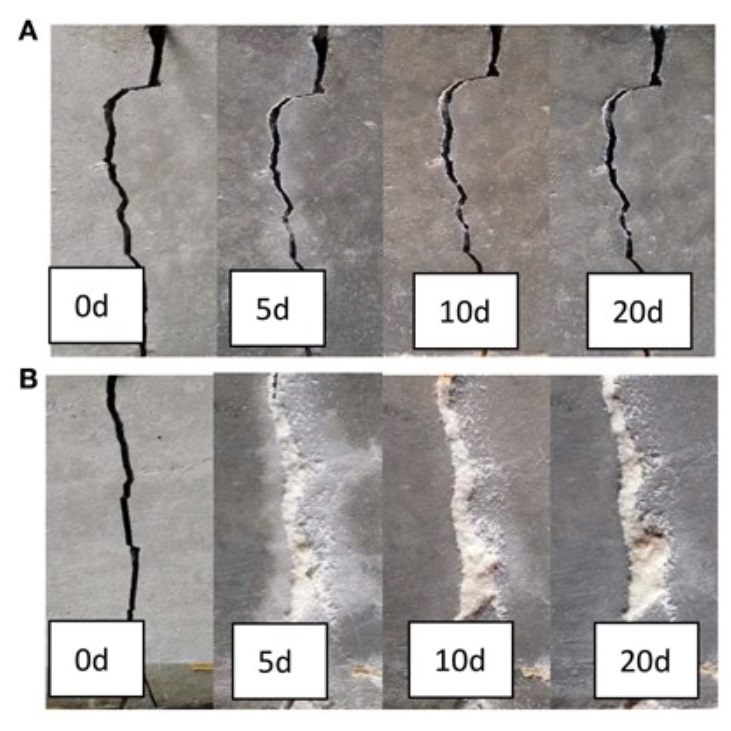

Lysinibacillus sphaericus is an alkaliphilic bacterium known for its potential application in the field of concrete healing or self-healing concrete. This process involves the use of this bacterium to autonomously repair cracks that develop in concrete structures over time. Here's how this process works:

- L. sphaericus bacteria are added to the concrete mixture during the construction phase. These bacteria are typically encapsulated in calcium alginate beads or other protective materials to keep them dormant until needed.

- When cracks form in the concrete due to various factors such as shrinkage, environmental stress, or structural damage, moisture penetrates the cracks and reaches the dormant Lysinibacillus sphaericus bacteria.

- In the presence of moisture and a source of nutrients, the bacteria become active consuming the nutrients (usually calcium lactate or other calcium-based compounds) and metabolizing them to calcium carbonate CaCO3.This calcium carbonate precipitates and fills the cracks in the concrete.

Fungi

Fungal biomaterials

Most industrially fabricated materials (construction and packaging) nowadays are non-recyclable and environmentally unfriendly. They consumes energy, limits natural resources, and pollute the air, soil, and water during production, transportation, and demolition. The carbon release during manufacturing of construction materials represent 8 to 10% of the global total carbon dioxide emissions. In the recent years, an increasing number of studies have shown that there is a possibility for producing bio-composites materials from the mycelium of fungi. Mycelium is composed of miles of hyphae developing on organic substrates such as straw, coffee husk, wheat brand, creating a superdense network of threads. They degrade lingocellulosic substrates, assembling together, forming a block-like structure. As mycelium can grow easily on organic materials, they have the potential to become the material of choice for a wide variety of applications. Mycomaterials are recyclable and of low cost. and can even be selected by designers or architects to be used for packaging and building industries.

Many fungi from the Ganoderma or Pleurotus or Trametes genera are nowadays used in biomaterial production especially in the construction and packaging sector as an alternative to polystyrene and plastic packaging. Different products can be produced because they can be molded into different shapes and with low density.

Plasmids

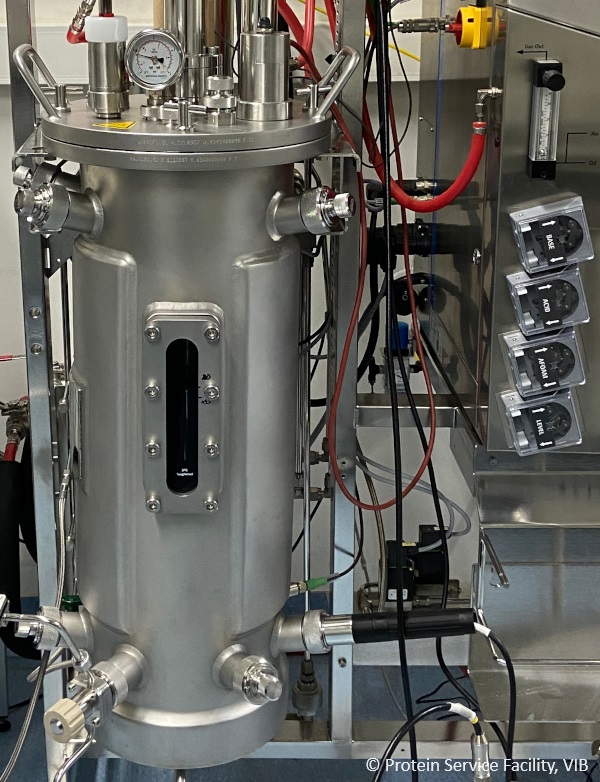

Protein production

Proteins are used everywhere today, just think of the enzymes needed to recycle paper or bleach your laundry and pharmaceutical products like insulin an antibodies. These can all be produced on a massive scale in bioreactors. After selecting a suitable microorganism that can express the desired protein, scientists manipulate it’s DNA to incorporate the gene encoding that. Growth conditions like temperature, pH and oxygen levels are all fine-tuned in a bioreactor, to maximize protein production. After isolating and purifying the proteins, they are ready for use.